Poketone-Polyketone

Poketone-Polyketone is a brand new eco-friendly thermoplastic comprised of CO and Olefins. This ground-breaking material contains a unique balance of excellent properties well suited for diverse applications. Through our relationship with world renown Hysoung Corporation, we help to deliver this original product to your doorstep.

Explore the technical data for all available Poketone-Polyketone grades here.

Applications

Automotive Technology

- Superior chemical/oil resistance and gas barrier properties for auto components.

Electrical/Electronics

- Utilizing high-impact resistance, flame retardancy, and easy process-ability, Poketone-Polyketone offers quality/cost-efficient connectors, switches, wire jackets, and junction boxes.

Industrial Materials

- Design and manufacturing of industrial components is made easy with Poketone-Polyketone’s reliable chemical resistance and increased abrasion.

Extrusion

- Poketone-Polyketone is easily extruded and applicable to a variety of products including pipes, tubes, and sealing materials.

Chemical Processing

- The semi-crystalline structure of Poketone-Polyketone possess extraordinary chemical resistance to aliphatic and aromatic intermediates found in oil, gas, and chemical processing industry environments. Poketone-Polyketone is also compatible in areas which contain salts, mild acids/bases, fuels, crude oil, and natural gas.

- Wear and abrasion resistance makes Poketone-Polyketone the ideal material for challenging sealing applications such as process valve seats and fluid handling equipment-seals.

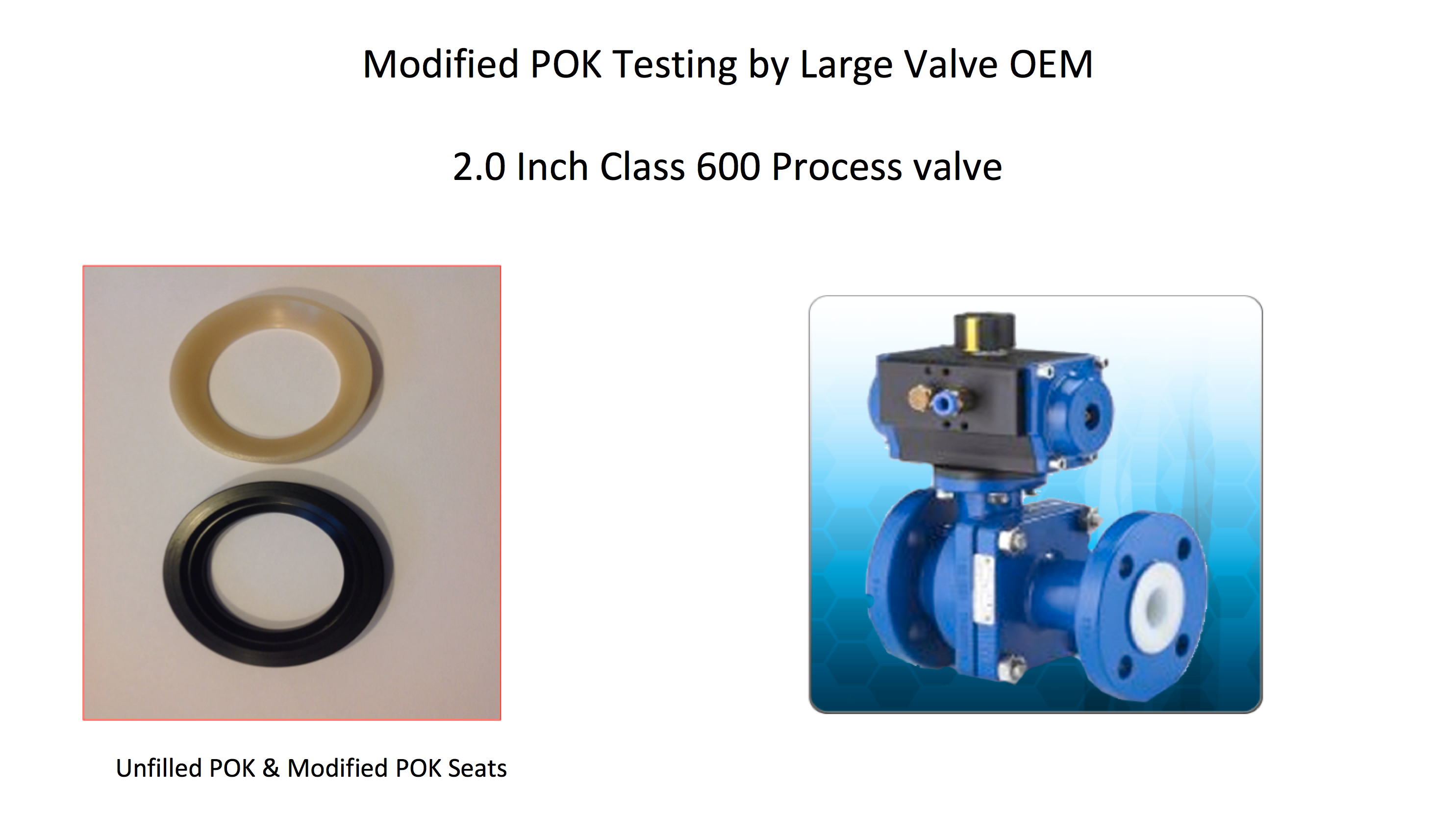

Success Story

A valve OEM tested a lubricated grade of Poketone-Polyketone in a 2″ class 600 ball-valve up to 250ºF under a load of 1500 psi. The Poketone-Polyketone seats were switched hundreds of times with minimal torque increase at elevated temperature. Seats made from Acetal polymer––a common valve seat material tested with the same conditions––exhibited a torque increase at 250ºF and 1,500 psi greater than 250%. The Poketone seats torque increase was only 35%.

Valve-Seat Operation

Critical service valves depend on soft-seating materials to adequately perform at pressures higher than 600 psi and temperatures above 250ºF. The seats must maintain a seal when pressurized and depressurized at room temperature, as well as when at temperatures higher than 250ºF.

A critical valve must be cycled several hundreds of times at pressure and at elevated temperature. Commonly used seat polymers such as acetal, nylon, and PEEK generate high torques when the valves are cycled under pressure at elevated temperature. This elevated torque condition can be greatly reduced or eliminated when using as a seating material such as POKETONE-aliphatic polyketone-polymer. The inherent low coefficient of friction, low moisture absorption, and self-lubricating characteristics of POKETONE makes this polymer ideal for valve seating material.

In a recent test, an ANSI 600 class ball valve equipped with POKETONE-POLYKETONE seats demonstrated a very low torque increase when switching the valve hundreds of times. Torque increase at 1,500 psi at 250ºF was only 33%. The same valve equipped with Acetal POM seats showed a torque increase in excess of 300%. POKETONE-aliphatic-polyketone should be considered the material of choice for critical service valves when seal reliability is key to valve performance. POKETONE-POLYKETONE truly generates peace of mind in valve operation.

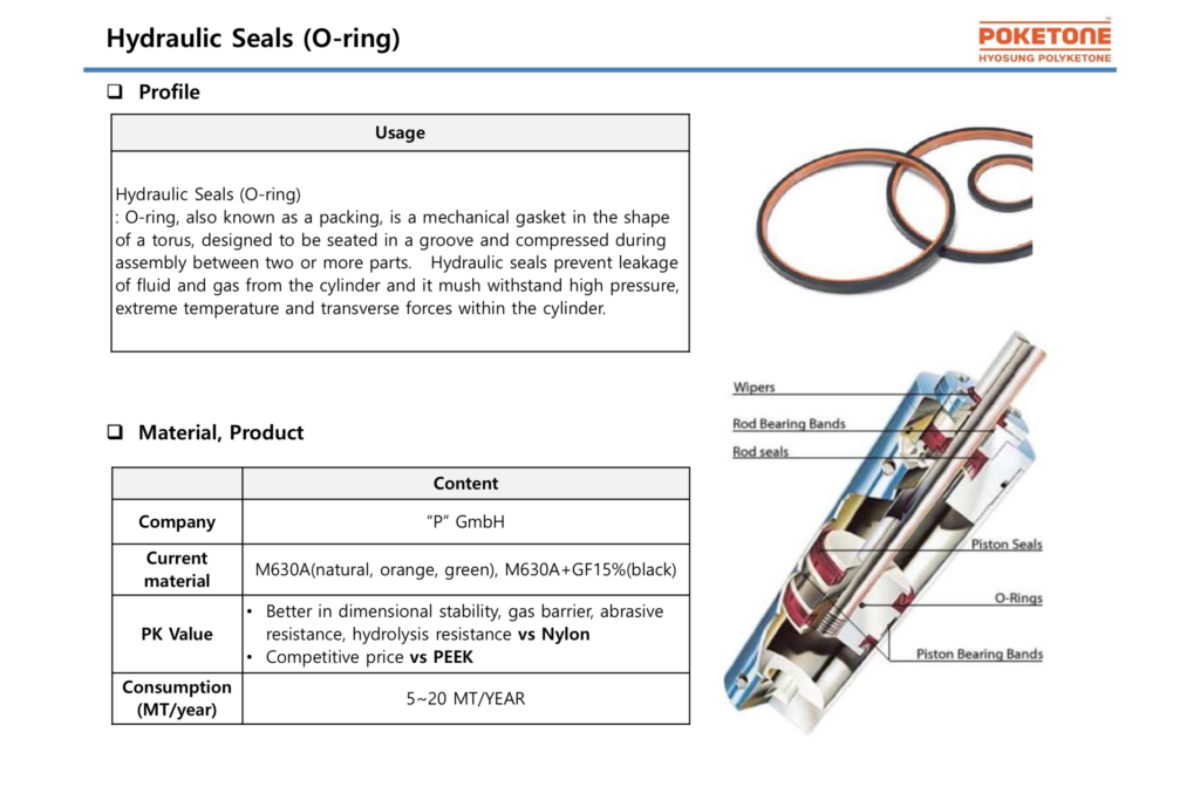

Explore our thorough hydraulic-seals guide for O-rings below.